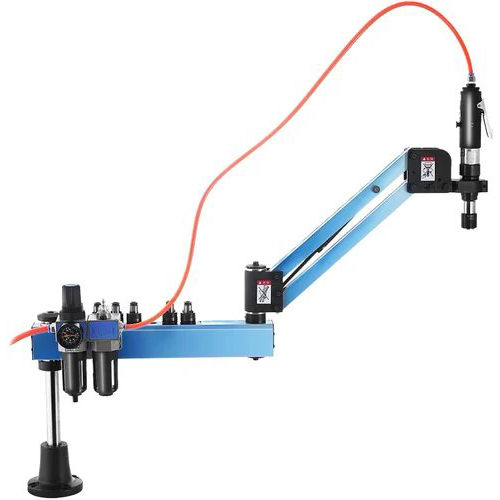

ElectroMagnetic Drilling And Tapping Machine

160000 INR/Piece

Product Details:

- Condition New

- Spindle Speed 220/350 rpm

- Diameter Up to 35 mm

- Motor Power 1200 W

- Machine Type Drilling & Tapping

- Features Magnetic base, precise drilling, tapping functionality

- Frequency 50 Hz

- Click to View more

X

ElectroMagnetic Drilling And Tapping Machine Price And Quantity

- 160000 INR/Piece

- 1 Piece

ElectroMagnetic Drilling And Tapping Machine Product Specifications

- Electric

- 340 x 330 x 430 mm

- 1200 W

- Adjustable

- Semi-Automatic

- 13 35 mm (Drilling), M6 M20 (Tapping)

- No

- No

- High-grade Alloy Steel

- Low (<75 dB)

- 440V Volt (v)

- 190 x 180 mm

- Electromagnetic Control

- New

- 220/350 rpm

- Up to 35 mm

- 22 kg

- 1200 W

- Industrial drilling and tapping

- ElectroMagnetic Drilling And Tapping Machine

- Magnetic base, precise drilling, tapping functionality

- 50 Hz

- Drilling & Tapping

- White/Black

ElectroMagnetic Drilling And Tapping Machine Trade Information

- 7-10 Days

Product Description

Presenting a scarce, gilt-edged ElectroMagnetic Drilling and Tapping Machinean enlightened solution for precision industrial tasks. Utilise this excellent offer for an outstanding deal: featuring 13,000 N max magnetic adhesion, core drill capacity of 1235 mm, and an integrated coolant system. Forward/Reverse rotation and semi-automatic operation ensure superior usability. Built from high-grade alloy steel, it boasts precise drilling and tapping, extended service life, and IP54 protection. Secure your industrial productivity with this sophisticated, power-packed machine, designed for exporter, importer, manufacturer, supplier, and trader needs across India.

Superior Competitiveness & Versatility for Industrial Applications

The ElectroMagnetic Drilling and Tapping Machine stands out for its plant-ready rugged performance and unmatched accuracy. Its gilt-edged magnetic base ensures stability during intense operations. The machine excels in manufacturing, fabrication, and heavy engineering segments, adept at precise drilling and tapping from 13 to 35 mm on high-grade alloy steel. Utilise this offer to increase efficiency in applications where reliability, longevity, and minimal noise (<75 dB) are essential. It is perfectly suited for workshops and industrial plants.

Reliable Supply, Secure Packaging & Trusted Dispatch Mechanism

Benefit from our streamlined packaging and dispatching protocolseach machine is delivered in robust wooden boxes to ensure safety. Prompt packing & dispatch is guaranteed through advanced logistics, meeting diverse customer requirements across bulk or regular needs. Our supply ability meets large-scale industrial projects, supported by flexible payment terms and verifiable certifications. All shipments undergo rigorous checks prior to dispatch, ensuring you receive only authentic, compliant, and well-protected machinery, ready for immediate use.

Superior Competitiveness & Versatility for Industrial Applications

The ElectroMagnetic Drilling and Tapping Machine stands out for its plant-ready rugged performance and unmatched accuracy. Its gilt-edged magnetic base ensures stability during intense operations. The machine excels in manufacturing, fabrication, and heavy engineering segments, adept at precise drilling and tapping from 13 to 35 mm on high-grade alloy steel. Utilise this offer to increase efficiency in applications where reliability, longevity, and minimal noise (<75 dB) are essential. It is perfectly suited for workshops and industrial plants.

Reliable Supply, Secure Packaging & Trusted Dispatch Mechanism

Benefit from our streamlined packaging and dispatching protocolseach machine is delivered in robust wooden boxes to ensure safety. Prompt packing & dispatch is guaranteed through advanced logistics, meeting diverse customer requirements across bulk or regular needs. Our supply ability meets large-scale industrial projects, supported by flexible payment terms and verifiable certifications. All shipments undergo rigorous checks prior to dispatch, ensuring you receive only authentic, compliant, and well-protected machinery, ready for immediate use.

FAQs of ElectroMagnetic Drilling And Tapping Machine:

Q: How does the integrated coolant system enhance the machines operation?

A: The integrated coolant system helps maintain optimal temperatures during drilling and tapping, reducing wear on tools, increasing service life, and ensuring consistent performance even in long operation cycles.Q: What are the primary benefits of the electromagnetic base?

A: The electromagnetic base provides strong adhesion (up to 13,000 N), preventing movement during drilling or tapping, which results in more accurate, safe, and precise operations, especially in vertical and overhead applications.Q: Which industries can utilise this drilling and tapping machine most effectively?

A: Industries such as fabrication, heavy engineering, automotive, and manufacturing plants find this machine most beneficial due to its high precision, adjustable cutting area, and robust performance on alloy steel.Q: What is the process for packaging and dispatching the machine upon order?

A: Each machine is securely packed in a wooden box, then dispatched through reliable logistics partners to ensure timely and damage-free delivery, with full certification and documentation included.Q: How does the machines semi-automatic grade influence its usage?

A: Being semi-automatic allows users to maintain control over essential operations while benefiting from the machines precision and reduced manual effort, making it ideal for repetitive tasks and medium production volumes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free