Friction Welding Machine

6500 INR/Unit

Product Details:

- Rod Diameter 6-50 mm

- Weight 1200 kg

- Arc Current 300 A

- Usage Welding

- Output Current 300 A

- Input Current 40 A

- Power 15 kW

- Click to View more

X

Friction Welding Machine Price And Quantity

- 6500 INR/Unit

- 1 Unit

Friction Welding Machine Product Specifications

- 300 A

- 40 A

- 6-50 mm

- Welding

- 1200 kg

- 300 A

- Water Cooling

- 3200 mm x 1200 mm x 1600 mm

- Friction Welding Machine

- 380 V

- Adjustable (0-250 Hz)

- High-Strength Metal Joining

- F

- New

- 15 kW

- 92%

- 20 mm x 50 mm

- 50 Hz

- Three Phase Induction Motor

Friction Welding Machine Trade Information

- 15 Unit Per Month

- 3-15 Days

- South America, Western Europe, Central America, Asia, North America, Eastern Europe, Middle East, Australia, Africa

- All India

Product Description

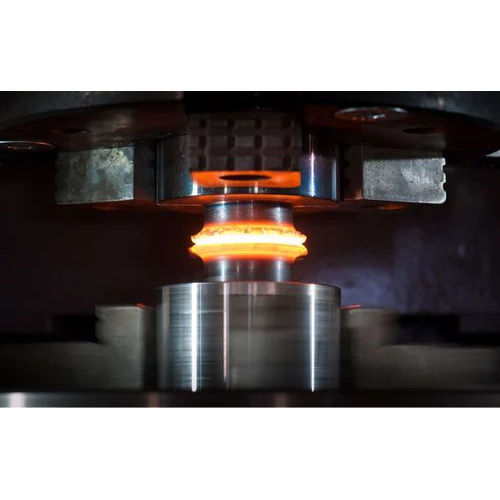

Friction Welding Machine

Friction Welding Machine is a highly demanding industrial unit that is used to make rigid weld joints using heat produced due to friction in between two work parts that are going to be welded. It is equipped with high-speed drives that make it easier to rotate the workpiece at high speed. The working mechanism is encased in a rigid enclosure that gives excellent protection to the operator from harsh working conditions. The offered Friction Welding Machine can be delivered to our customers with a supply ability of 15 units per month.

Efficient and High-Strength Metal Joining

The friction welding machine offers exceptional efficiencyoperating at 92%and delivers robust, high-strength metal joints. With a powerful three-phase induction motor and programmable cycles, it ensures precision and repeatable results in industrial settings. The systems water cooling and automatic lubrication keep the machine running smoothly, minimizing downtime and maintenance.

Advanced Safety and Intuitive Controls

Engineered for operator safety, this machine comes equipped with an emergency stop button, overload protection, and a digital touch screen for easy operation. The PLC control system allows for seamless automation or manual intervention, offering flexibility for various welding requirements while maintaining maximum operational safety and reliability.

FAQs of Friction Welding Machine:

Q: How does the friction welding machine enhance production efficiency?

A: The machine operates at up to 2400 rpm spindle speed, supports programmable welding cycles (up to 500), and features high automation through PLC control, digital touch screen operation, and automatic centralized lubrication, enabling faster workflows and minimizing manual intervention.Q: What safety features are included in this friction welding machine?

A: It is equipped with an emergency stop button and overload protection to ensure operator and equipment safety during operation, reducing risks in demanding industrial environments.Q: When should I use the manual and automatic operation modes?

A: The manual mode is ideal for custom or low-volume tasks requiring close supervision, while automatic mode streamlines repetitive or bulk welding jobs, ensuring consistent results with minimal oversight.Q: Where can this friction welding machine be utilized?

A: This machine is suitable for industrial settings such as fabrication shops, automotive manufacturing, and metalworking industrieswhere high-strength metal joining is necessary. It is supplied to manufacturers, exporters, importers, and traders, primarily in India.Q: What is the process of setting up a welding cycle on this machine?

A: Setting up involves configuring parameters on the digital touch screen, with the PLC system allowing you to program up to 500 welding cycles, which ensures precise and repeatable welds as per your requirements.Q: What are the key benefits of using this friction welding machine?

A: Key benefits include high-strength, consistent joints, efficient operation at low noise levels (<70 dB), minimal downtime with automatic lubrication, and robust safety mechanisms, all contributing to superior productivity and equipment longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free